work in process inventory is highest in

Ending WIP is listed on the companys balance sheet along with amounts for raw materials and finished goods. Consequently production operates with continuously low work-in-process inventory levels with high efficiency.

Inventory Management Workflow Inventory Management Management Business Process Management

These items are either just being fabricated or waiting for further processing in a queue or a buffer storage.

. The WIP figure indicates your company has 60000 worth of inventory thats neither raw material nor finished goodsthats your work in process inventory. Reporting Work In Process Inventory With Fifo. These items are typically located in the production area though they could also be held to one side in a buffer storage area.

There was no beginning work in process and ending work in process was 50 complete. 49000 178 670000 362 Total Assets. Work in process is goods in production that have not yet been completed.

The beginning work-in-process inventory is recorded at the beginning of the accounting period and the end work-in-process inventory is recorded at the end of the period. By Sarah Harris August 27 2021 5 min read. Most importantly its hugely important when youre considering a companys future growth potential.

Advantages Of Wip Inventory. The cost of work-in-process typically includes all of the raw material cost related to the final product since raw materials are usually. It doesnt take into account waste scrap spoilage downtime and MRO inventory.

A Mass customization b Process focus c Repetitive focus d Product focus. Select Suppliers to dav Select small and more frequent deliveries large and less frequent deliveries prompt deliveries and delivery size does not matter. Which strategy is Company ABC utilizing.

Work in Progress WIP Inventory includes material that has been released from the inventory for the process but not yet completed and is waiting for a final inspection. Work-in-progress WIP inventory is in the process to become finished goods it helps in earlier conversion to the finished goods and improves the turnaround cycle. This essential category covers everything from manufacturing to construction.

The more WIP inventory that goes through the production process the higher the raw materials and labor costs will be which will impact the total costs of manufactured goods. Company ABC utilizes a process strategy that involves highest volume of work in process inventory. With the formula above this would give you a beginning work in process inventory of 571830.

A vital part of inventory management is work-in-process inventory. Materials cost was 225000 labor cost was 275000 and 400000 of overhead was applied to production. Work-in-process inventory often known as WIP inventory is pretty much its own field of expertise.

10000 300000 - 250000 60000 Work in process inventory 60000 Work in process vs Work in progress Work in process and work in progress are often used synonymously. This means that Crown Industries has 10000 work in process inventory with them. Compute the cost per unit produced.

Workers to be. Leave a Comment Accounting By admin. Understanding Work in Process.

A work-in-progress WIP is the cost of unfinished goods in the manufacturing process including labor raw materials and overhead. WIPs are considered to be a current asset on the balance sheet. For the exact number of work in process inventory you need to calculate it manually.

However by using this formula you can get only an estimate of the work in process inventory. Work in Process Overview Work in process inventory is an asset The ending work in process inventory is simply the cost of partially completed work as of the end of the accounting period. The ending inventory was 90 complete for materials and 40 complete for conversion costs.

This requires the following to be used in the production process. What Is The Difference Between work In Process And work In Progress Inventory. 11000 40 260000 140 Total Inventories.

Inventory in this classification typically involves the full amount of raw materials needed for a product since that is usually included in the product at the. 26000 94 240000 129 Finished Goods. The ending work in process inventory is then valued at.

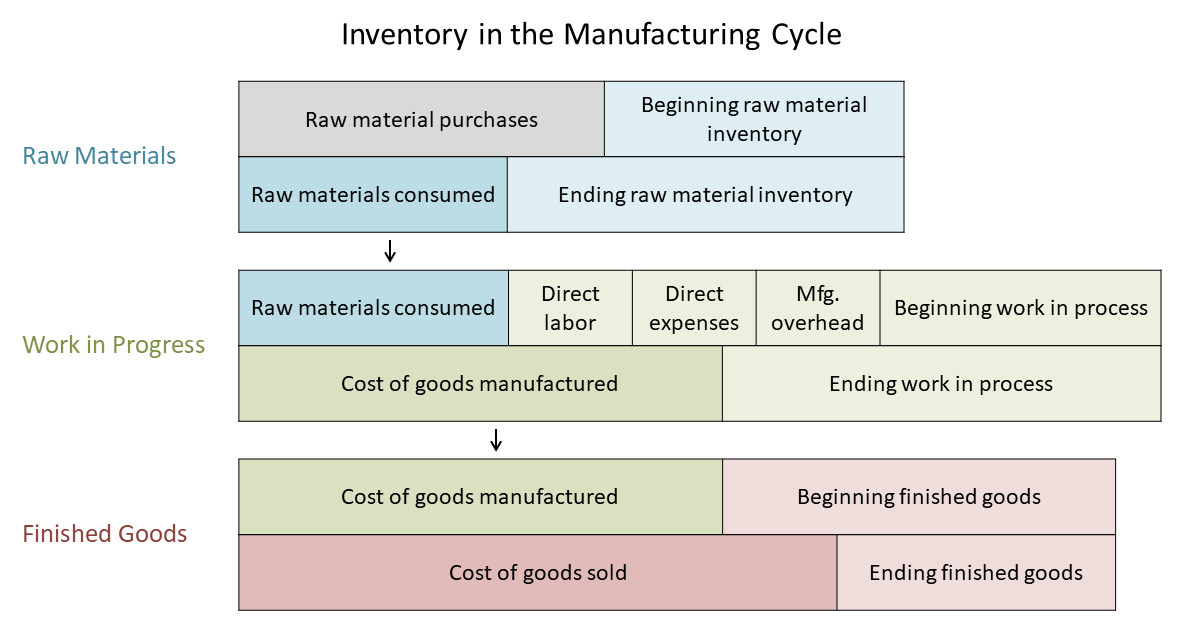

The work-in-process inventory tracks inventory cost throughout the manufacturing process. Keep in mind this value is only an estimate. Over the year the company incurs 300000 in production costs and produces finished goods at a cost of 250000.

Select Productions to be. WIP Inventory Work-in-Progress is defined as the goods which are in different stages of production. The formula is as followed.

8000 240000 238000 10000. Ending work-in-process inventory May 31 24000 The beginning inventory was 60 complete for materials and 20 complete for conversion costs. These goods are situated between raw materials and finished goods in the production process flow.

What Is Work In Process Wip Inventory How To Calculate It. 275000 100 1850000 100. Is work in process inventory.

Is High or Low Best. Yes work in process WIP inventory is considered inventory. Work-in-process inventory is materials that have been partially completed through the production process.

225000275000400000 70000 5000 50 90000072500. Work in process inventory 60000. Raw Materials Direct Labor Costs Manufacturing Overhead Manufacturing Costs 3.

As an example lets say your current COGS is 5000 your ending inventory balance is 964240 and your cost of purchases is 892410. Sometimes the accounting system accounts for the semi-finished goods in this category. Work in process WIP work in progress WIP goods in process or in-process inventory are a companys partially finished goods waiting for completion and eventual sale or the value of these items.

Work in Process. WIP helps in the continuous process of the production of goods if WIP inventory is not considered then it leads to some idle time in production as all inventories can either be in the state of raw. Company ABC utilizes a process strategy that involves highest volume of work in process inventory.

Higher is Better Inventory Turnover Work-In-Process Only KPI Details Inventory Turnover Work-In-Process Only measures the rate at which a companys inventory of work-in-process WIP materials move on to completion and are replaced ie turned over a given period of time. Cost of manufactured goods.

Inventory Management Software In 2020 Inventory Management Software Software Management

How To Use Inventory Control Software In Your Business Inventory Management Software Inventory Management Inventory

Supply Chain Infographics Listing The Steps In Manufacturing Process Slide01 Supply Chain Infographic Supply Chain Logistics Management

Work In Process Wip Inventory Youtube

Senior Executive Commercial Bangalore Job Openings Job Opening Job Good Interpersonal Skills

Work In Process Inventory Formula Wip Inventory Definition

Inventory Planning And Management Inventory Planners Need To Have Their Slide Rule Or Their Calculators Like Any O How To Plan Types Of Planners Supply Chain